Medway Local Plan (Regulation 18, 2024)

11.1 Introduction

11.1.1 As the Minerals Planning Authority for Medway, Medway Council provides planning policy, and determines planning applications, related to the supply of minerals in Medway. This section sets out the planning policy for development related to the supply of minerals in Medway.

Policy context

11.1.2 The NPPF contains the Government's overarching policies on minerals planning. The NPPF identifies a need to ensure that a sufficient supply of minerals is available to support the economy and states that great weight should be given to the economic benefits of minerals extraction when determining applications, whilst also making clear that minerals should be used sustainably. It identifies a range of mineral resources that are of 'local and national importance' for which planning authorities should have policies in their Local Plans.

11.1.3 The NPPF requires Mineral Planning Authorities (MPAs) to aim to source minerals supplies indigenously and, so far as practicable, take account of the contribution that substitute, or secondary and recycled materials and minerals waste would make to supply, before considering extraction of primary materials. For land-won primary materials the NPPF expects MPAs to identify, and include policies for the extraction of, mineral resources of national and local importance in their area.

Minerals in Medway

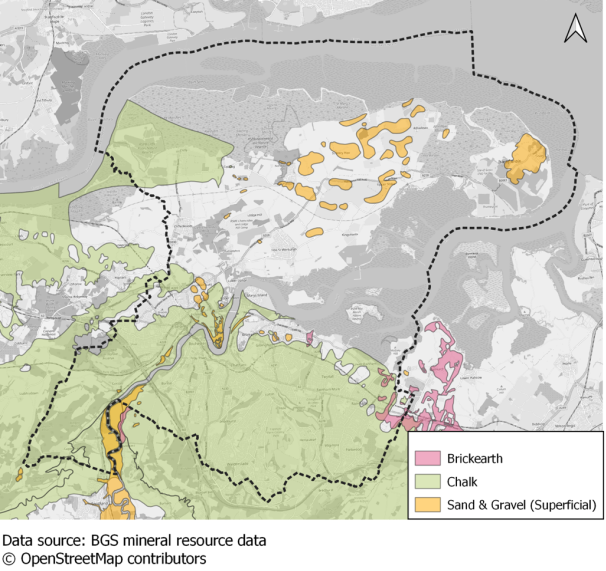

11.1.4 Minerals of 'local and national importance' that exist within Medway are sharp sand and gravel (aggregates), chalk and brickearth.[9] As shown on Figure 9, much of the sand and gravel resource is located on the Hoo Peninsula, and brickearth to the south of the Medway estuary.

Figure 9: Economic Geology of Medway

11.1.5 In recent times sand and gravel has been the only mineral actively extracted in Medway. Sand and gravel are essential aggregate materials used primarily in concrete, with substantial quantities being used for construction fill. 'Soft' sand is a particular sub-category of sand and gravel used in mortars and asphalt.

11.1.6 The supply of, and demand for, aggregate in Medway is monitored on an annual basis and the results are reported in the Medway 'Local Aggregates Assessment' (LAA). Currently there are only two permitted quarries for the extraction of 'sharp' sand and gravel in Medway, one inactive and the other commencing extraction in 2017:

- Kingsnorth Quarry

- Perry's Farm (currently inactive)

11.1.7 The current permission for extraction at Kingsnorth Quarry expires on 1 May 2027.

11.1.8 At the end of 2022, the permitted reserve of sand and gravel in Medway was 0.372Mt and the landbank was 5.2 years. Due to production at the Kingsnorth Quarry site only commencing in 2017 the 3-year average of sales has been used to calculate the landbank rather than 10‐year average sales.[10]

11.1.9 The sand and gravel deposits in the Medway area are primarily concentrated on the Hoo Peninsula where river terrace sands and gravels proven resources may be in excess of 1.6 million tonnes, with between 0.9 million tonnes and 3.6 million tonnes of unproven resources, plus buried channel sand and gravel potential resources of 35.6 million tonnes.

11.1.10 There is no significant soft sand resource in Medway. Historically soft sand requirements in Medway (for use in mortar and asphalt) have been met by resources in Kent and so Medway's requirements for soft sand are captured within Kent's LAA and its needs are planned for in the Kent Minerals and Waste Local Plan.

11.1.11 There are no crushed rock mineral resources in Medway although there are local ragstone resources in Kent. Substantial, and strategically significant, quantities of crushed rock are imported to wharves in Medway from other countries including Northern Ireland, Scotland and Norway.

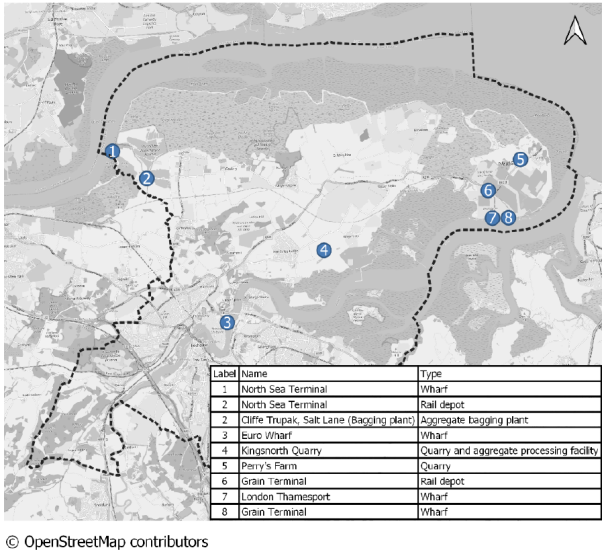

11.1.12 Medway currently has four wharves that are used for the importation of aggregates:

- Grain Terminal, Isle of Grain (wharf and rail depot)

- North Sea Terminal, Cliffe, Rochester (wharf and rail depot)

- Euro Wharf, Frindsbury, Rochester

- London Thamesport, Isle of Grain

11.1.13 Marine dredged sand and gravel is landed along with crushed rock. Together these wharves are operating well within their capacity of 4.30 million tonnes per annum (Mtpa) and so there is potential to increase throughput in response to market demand. Two of the wharves, at Cliffe and the Isle of Grain, have associated rail depots which allow for export, and import, of aggregate by rail.

11.1.14 Facilities exist within Medway for the recycling of construction, demolition and excavation (C,D&E) waste at fixed sites to produce recycled aggregate. There is also additional capacity, where significant amounts of material are dealt with on site by mobile plant as part of demolition and construction processes. Secondary aggregate may also be supplied from a stock of coal derived fly ash that was produced during the operation of the, now demolished, Kingsnorth Power Station.

11.1.15 Other minerals supply infrastructure includes an aggregate bagging plant at Cliffe and a temporary aggregate processing plant at Kingsnorth Quarry.

11.1.16 Figure 10 shows the location of all currently permitted mineral supply facilities in Medway.

Figure 10: Minerals Supply Facilities in Medway

11.1.17 The following Vision and Objectives for minerals supply set out the Plan's approach to allowing for the supply of minerals in Medway.

Vision for Minerals Supply

Medway's economic mineral resources may be worked to meet needs and will be safeguarded from unnecessary sterilisation and for use by future generations. Wharves and rail depots will continue to be utilised for the importation and distribution of minerals and will be safeguarded for this purpose. A positive legacy will be left by mineral supply development in Medway.

Objectives for minerals supply

The Plan's objectives for minerals supply are to:

- safeguard economic mineral resources;

- safeguard mineral supply infrastructure from other development;

- make best use of primary mineral resources;

- maximise the production and use of recycled aggregate from construction and demolition, as well as secondary aggregate, in place of primary aggregate;

- meet demands for minerals in Medway and elsewhere without compromising the quality of Medway's natural and built environment; and,

- restore quarries to a high standard in a manner that benefits the community and environment of Medway.

11.2 Safeguarding mineral resources

11.2.1 Minerals Safeguarding Areas (MSA) cover areas of land where there are known geological deposits of minerals which are desired to be kept safeguarded from unnecessary sterilisation by surface development. Identification of the MSA has included consideration of the following:

- Areas where the mineral of economic importance is known to exist;

- existence of surface development which has caused the minerals to be sterilised; and,

- allocations for other forms of development in this Plan

11.2.2 The economic viability of exploiting the buried channel sand and gravel is unknown and the likely impact of the extraction methods could be substantial, therefore only the identified reserves of river terrace sand and gravel are safeguarded by this Plan.

11.2.3 A 'Minerals Consultation Area' (MCA) is applied to the MSA which includes the MSA and extends 250 metres from its boundary. Planning applications for development not exempt from minerals safeguarding within the MCA will need to be accompanied by a Mineral Assessment (MA) which shows how safeguarding of the mineral resource has been considered including:

- potential extent of sterilisation which could occur as a result of the development;

- extent or distribution of survey boreholes/pits;

- site specific considerations;

- options for prior extraction; and,

- economic viability of the mineral, i.e. the local market interest.[11]

11.2.4 The Policies Map shows the extent of the MSA and Minerals Consultation Areas in Medway.

11.2.5 Safeguarding does not rule out non minerals development coming forward within an MSA and the certain circumstances in which proposals will be acceptable are stipulated in the policy below.

(4) Policy T30: Safeguarding Mineral Resources

Planning permission will only be granted for development that is incompatible with safeguarding mineral resources within the Mineral Safeguarding Areas, or development in a location which might hinder access to the mineral resource, where it is demonstrated that either:

- the mineral is not of economic value or does not exist; or

- that extraction of the mineral would not be viable or practicable; or

- the mineral can be extracted satisfactorily, having regard to the need to demonstrate no unacceptable adverse impacts to the environment or communities and is for a temporary period, prior to the non-minerals development taking place without adversely affecting the viability or deliverability of the non-minerals development; or

- the incompatible development is of a temporary nature that can be completed and the site returned to a condition that does not prevent mineral extraction within the timescale that the mineral is likely to be needed; or

- material considerations indicate that the need for the development overrides the presumption for mineral safeguarding such that sterilisation of the mineral can be permitted following the exploration of opportunities for prior extraction; or

- it constitutes development that is exempt from mineral safeguarding policy, namely: Householder applications; infill development of a minor nature in existing built-up areas; advertisement applications; reserved matters applications; minor extensions and changes of use of buildings; minor works; and non-material amendments to current planning permissions.

11.2.6 Mineral safeguarding is an essential way of ensuring that future generations are able to access the minerals that they may require to meet their needs. The NPPF expects Minerals Planning Authorities to safeguard minerals by identifying MSAs to ensure that mineral resources are not needlessly sterilised by non-mineral development.

11.2.7 Some forms of development requiring planning permission will have no, or negligible, impacts on the mineral resource and it is important that this is made clear to avoid unnecessary constraints on development and burdens on developers.

11.2.8 As development in proximity to a mineral resource may hinder access to the resource, it is also necessary for the impact of such proposals to be considered and hence MCAs have also been identified which extend beyond the MSA.

11.3 Safeguarding of existing mineral supply infrastructure

11.3.1 Minerals supply infrastructure constitutes storage, handling and transport facilities and includes the following:

- Wharves

- Rail depots

- Recycled and secondary aggregate production facilities

- Mineral processing facilities including:

- mortar plants;

- facilities for the manufacture of coated materials, e.g. asphalt;

- facilities for concrete batching and manufacture of concrete products; and

- bagging plants.

11.3.2 Minerals supply infrastructure with permanent planning permission, and their proximity, will be safeguarded against development that could prejudice or adversely affect their operation. The area safeguarded is that delineated by the boundary associated with the planning permission for the site. A list of safeguarded mineral supply infrastructure in Medway and maps with indicative boundaries are shown on the Policies Map and will be maintained and updated in the Medway Annual Monitoring Report.

11.3.3 Minerals Consultation Areas which extend 250m from the boundaries also apply to all of the identified mineral supply infrastructure.

11.3.4 Where it is demonstrated that a proposed development may affect the operation of mineral supply infrastructure, proposals for replacement, compensatory, capacity must be provided of at least equivalent tonnage, accessibility, location in relation to the market, suitability, and availability of land for processing and stockpiling of materials. In the case of wharves, replacement capacity must include consideration of the size of the berth(s) for dredgers, barges or ships, ensuring the depth and tidal flows (including any potential for 24-hour operation according to tidal movements) are equivalent.

11.3.5 Facilities used for the production of recycled aggregate using Construction and Demolition waste are also safeguarded.

(5) Policy T31: Safeguarding of Existing Mineral Supply Infrastructure

Identified mineral supply infrastructure will be safeguarded from development that would prejudice or prevent their operation.[12] Such development will only be allowed in exceptional circumstances where it is demonstrated that:

- the proposed site is already allocated for other non-mineral uses in the Local Plan; or

- the facility is no longer required; or

- material considerations indicate that the need for the proposed development overrides the presumption to safeguard; or

- alternative equivalent provision for the loss of the importation or distribution facility can be made elsewhere in Medway.

11.3.6 Minerals supply infrastructure is essential to the effective supply of minerals. Without such infrastructure minerals cannot be supplied, processed and transported. National policy requires MPAs to safeguard such infrastructure, recognising that other development pressures could mean capacity is otherwise lost.

11.3.7 Medway makes a critical contribution to the development of essential infrastructure in London and the South East by importing aggregates through its wharves. Associated rail depots allow for sustainable and efficient transportation of the aggregate from Medway, therefore providing valuable infrastructure for the distribution of aggregates to London and the wider South East region.

11.3.8 Safeguarding wharves and rail depots ensures Medway can continue to contribute to the importation and distribution of aggregates by preventing development that would prejudice or prevent their use.

11.3.9 A 250 metre consultation area is included which ensures that consideration is also given to whether applications falling within 250m of safeguarded development are likely to hinder the operations of existing minerals infrastructure.

11.3.10 To promote the continued use of secondary and recycled aggregates as a sustainable alternative to primary aggregates, current facilities must be safeguarded against development that would prejudice or prevent their operation.

11.3.11 National policy requires other types of mineral infrastructure to be safeguarded. This includes existing, planned, and potential sites for concrete batching, the manufacture of coated materials and other concrete products.

11.4 Supply of recycled and secondary aggregates

11.4.1 Recycled and secondary aggregates can provide an alternative to primary aggregate from land or marine won sources for a number of applications and, in‐line with government policy to secure the best use of finite primary mineral resources, the use of alternatives to primary aggregates as far as practicable is encouraged. Recycled aggregate is sourced from Construction and Demolition waste and may also be sourced from closed inert landfill sites and dredging disposal sites.

11.4.2 Industrial estates and sites where minerals supply, and waste management takes place may offer suitable locations for recycled and secondary aggregate production where the proposals are compatible with other policies set out in the development plan.

11.4.3 In locations where permissions for the existing use are temporary, for example in the case of a quarry, the development associated with recycled and secondary aggregates will usually only be permitted for the period of the host site's permission.

11.4.4 Proposals will also need to demonstrate consistency with other policies of this Plan intended to ensure that development does not give rise to unacceptable adverse impacts on communities or the environment as a whole.

(2) Policy T32: Supply of Recycled and Secondary Aggregates

Proposals for additional capacity for secondary and recycled aggregate production, including those relating to the expansion of capacity at existing facilities, will generally be supported in the following locations:

- Temporary demolition, construction, land reclamation and regeneration projects and highways developments where materials are either generated or to be used in the project or both for the duration of the project.

- Other mineral operations (including wharves and rail depots).

- Other waste management operations.

- Industrial estates.

Proposals for additional capacity for secondary and recycled aggregate production may be supported in other locations which are well located in relation to the source of input materials or demand for output materials and have good transport links.

Proposals to re-work old inert landfill sites and dredging disposal sites to produce recycled aggregate will be supported where it is demonstrated that net gains in landscape, biodiversity or amenity can be achieved by the operation and environmental impacts can be mitigated to an acceptable level.

11.4.5 The production of secondary and recycled aggregate is an industrial activity which lends itself to being located where similar activities are already taking place including industrial areas.

11.4.6 Quarries are generally located in rural areas and should be restored in a timely manner, and while they may offer suitable locations for the production of secondary and recycled aggregates while operational, ongoing operations might unduly delay their restoration and they are less likely to offer suitable locations for permanent facilities once the quarry has ceased operation.

11.5 Extraction of land won minerals

11.5.1 The likelihood of additional mineral extraction is uncertain in Medway, although if it occurs it is more likely that the sand and gravel, rather than the chalk and brickearth, resource will be worked over the period of this Plan.

11.5.2 The LAA (2022) identifies that there are very few sand and gravel reserves remaining and what does remain is expected to be fully worked out in the next few years. Despite this there has been no industry interest in establishing further reserves beyond the existing sites.

11.5.3 A nominal demand for land won sand and gravel of 72,000tpa is included in the latest LAA which suggests a landbank of 5.2 years at the end of 2022.[13] It is therefore considered unlikely that a minimum landbank of reserves equivalent to at least 7 years' supply will be able to be maintained over the Plan period.

11.5.4 Medway wharves are capable of supplying 4.3 million of tonnes of sand and gravel per year which is considered sufficient to meet current needs and provides potential for meeting future needs. However, should a proposal come forward, this will be supported depending on its nature and location and compliance with policies of this Plan.

11.5.5 Areas of Search for the working of sand and gravel within which planning permission may be granted, particularly if there is a potential shortfall in supply, are included on the Policies Map.

(2) Policy T33: Extraction of Land Won Minerals

Sand and gravel

Proposals for the extraction of sand and gravel within the Sand and Gravel Areas of Search shown on the Policies Map, will be acceptable in principle, provided it can be demonstrated that there is a need for the mineral to make a contribution to meeting local and regional requirements, and to achieve and maintain at least a 7-year landbank.

Proposals beyond the Sand and Gravel Areas of Search are not encouraged but may also be permitted depending on whether other sources are available to meet demand and any constraints can be overcome.

Industrial minerals

Proposals for the extraction of chalk and brickearth will be permitted which demonstrate there is a need for the mineral to meet the demands of new or existing plant.

The need for chalk should be demonstrated to be contributing to a stock of chalk reserves of at least 15 years to support a cement works.

The need for brickearth should be demonstrated to be contributing to a stock of clay reserves to supply brick works.

Restoration and aftercare

Proposals will need to demonstrate how mineral excavations will be restored in a timely manner that results in ongoing benefits to the local community and environment.

11.5.6 The NPPF requires Minerals Planning Authorities to plan for a steady and adequate supply of aggregates based on the assessment of supply and demand set out in the latest LAA. It also seeks for plans to make provision for the maintenance of landbanks of at least seven years for land-won sand and gravel.

11.5.7 The NPPF expects that, as appropriate, provision is made for land-won aggregates in Local Plans in the form of specific sites, preferred areas and/or areas of search and locational criteria. The Areas of Search in the Plan provide a guide to potential developers on the areas where sand and gravel resources are known to exist and working would be less likely to have an unacceptable adverse impact on communities and the environment and so planning permission may be more likely to be granted.

11.5.8 More generally, aggregate minerals are in constant demand and the sand and gravel resource in Medway may be exploited to contribute to meeting this demand. For this reason, Policy T33 does not quantify the amount of land won sand and gravel that should be provided from Medway, but instead it allows development to come forward where it is shown that a contribution to local and regional supplies can be made.

11.5.9 The NPPF expects local planning policy to ensure that worked land is restored at the earliest possible opportunity and to a high quality. Restoration of quarries should provide opportunities for BNG and may be included as part of Local Nature Recovery Strategies.

[9] Brickearth is a clayey silty loam used in the manufacture of bricks and tiles.

[10] Information regarding aggregate in Medway is taken from the Local Aggregates Assessment (LAA) 2020. An updated LAA taking account of sales in 2022 was published in December 2023. The landbank calculation is the permitted reserves divided by the LAA rate (average annual demand).

[11] Requirement for MAs to be included with planning applications is included in the local validation list.

[12] Identified in this document and subsequently in the Annual Monitoring Report.

[13] LAA 2022 based on 2022 data.